hard rock Crushing Plant:

hard rock Crushing Plant:

The Features of hard rock Crushing Plant:

Hamac adopts advanced technology, unique concept and reasonable design to manufacture hard rock crushers. So, all of our cobblestone crusher machines have many excellent features: Firstly, the clearance between the plate and the hammer can be adjusted conveniently, and the particle size can be controlled effectively; Secondly, the ore is broken along the joint surface, so the power consumption is low and the crushing efficiency is high; Thirdly, high chromium plate hammer has good impact resistance and abrasion resistance, and it also has powerful impact force; Lastly, crushing ratio of the rock crushing equipment is large, and the ratio can reach to 40%. So it can simplify the crushing process, can make the three section crushing into two or one section crushing, and reduce the equipment cost of the mineral processing factory.

Advantages of Jaw Crusher:

1. The discharge mode adjusting device with joint mode, is reliable and convenient. The adjustment range is large, which increases the flexibility of the equipment and can meet the needs of different customers.

2. The lubrication system is safe and reliable, the parts are easy to replace and the maintenance work is convenient.

Important parameters

Production capacity: 3-500 t/h

The maximum input size: ≤1020mm

The output size: 20-300mm

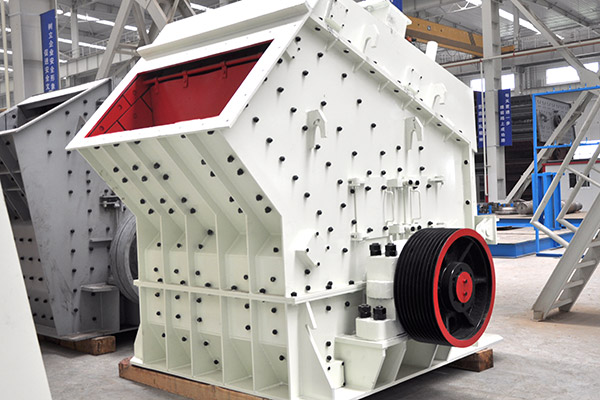

Advantages of PF impact Crusher:

The hammer bar is made of high chromium material and wear-resistant materials. After heat treatment, it has good resistance to mechanical and thermal shock.

A self-weight safety device is equipped. When unbreakable materials enter the crushing cavity, they'll be discharged automatically, and thereby the equipment can get protected.

Important parameters PF-1520

The maximum input size: 830×2050

The output size: 20-200mm

Rock Crusher Plans:

What factors should you take into consideration before you purchase a crusher? As one of a professional rock crushing companies, Hamac will give you some suggestions. Firstly, You should consider the size of raw materials you want to process. If the materials are very big particles, you can choose the primary crushing machine(jaw rock crusher). Because jaw crusher is suitable for crushing large stone materials. On the contrary, you should choose Hamac’s other kind of crusher machines(cone crusher or impact crusher) in order to crush smaller stone materials. Secondly, you should consider the performance of cheap rock crusher. Hamac, a reliable crusher supplier, adopts advanced technology to manufacture all kinds of crushers. Therefore, our crushers have simple structure, easy maintenance, stable performance and low operation cost. So you can choose our small rock crusher for sale without any hesitation. Lastly, price is a very important factor you should think about. We will recommend suitable crusher to different customers according to their budgets and requirements. We ensure that all customers will get best crusher with the most reasonable price. We usually use an impact crusher or a hydraulic cone crusher in this crushing stage. Impact crusher can crush materials which size are from 100mm to 500mm. And this kind of crusher has large crushing ratio. Besides, the finished material has very good shape. The hydraulic cone crusher realizes the effective combination of high performance crushing chamber and high crushing frequency. Both of the crushers have their own advantages, we should choose the crusher according to actual requirements.

Inquiry

Inquiry